Jim kadan kafin kaddamar da wayar iPhone ta farko, Steve Jobs ya yi kira ga ma’aikatansa kuma ya fusata game da tarin kura-kurai da suka bayyana a kan samfurin da yake amfani da shi bayan ‘yan makonni. Ya bayyana a fili cewa ba zai yiwu a yi amfani da gilashin daidaitattun ba, don haka Ayyuka sun haɗu tare da kamfanin gilashin Corning. Duk da haka, tarihinsa ya koma zurfi cikin karni na karshe.

Duk ya fara ne da gwaji guda daya da bai yi nasara ba. Wata rana a cikin 1952, Corning Glass Works chemist Don Stookey ya gwada samfurin gilashin hotuna kuma ya sanya shi a cikin tanderun 600°C. Duk da haka, yayin gwajin, kuskure ya faru a ɗaya daga cikin masu gudanarwa kuma zafin jiki ya tashi zuwa 900 ° C. Stookey ana sa ran samun narkakkar gilashin da tanderun da aka lalata bayan wannan kuskuren. Maimakon haka, ya gano cewa samfurin nasa ya zama farar fata mai madara. Yana kokarin kama ta sai ’yan tsantsa suka zame suka fadi kasa. Maimakon ta farfasa a kasa, sai ta sake komawa.

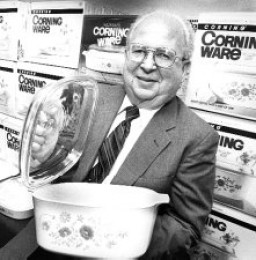

Don Stookey bai sani ba a lokacin, amma ya ƙirƙira yumburan gilashin roba na farko; Corning daga baya ya kira wannan abu Pyroceram. Ya fi aluminium ƙarfi, ya fi ƙarfin ƙarfe mai ƙarfi, kuma sau da yawa ya fi ƙarfin gilashin soda-lime na yau da kullun, ba da daɗewa ba ya sami amfani da komai daga makamai masu linzami na ballistic zuwa dakunan gwaje-gwajen sinadarai. An kuma yi amfani da shi a cikin tanda na microwave, kuma a cikin 1959 Pyroceram ya shiga gidaje a cikin nau'i na kayan dafa abinci na CorningWare.

Sabon kayan ya kasance babban riba na kuɗi ga Corning kuma ya ba da damar ƙaddamar da Muscle Project, babban ƙoƙarin bincike don nemo wasu hanyoyi don ƙarfafa gilashi. An sami ci gaba mai mahimmanci lokacin da masu bincike suka fito da hanyar ƙarfafa gilashin ta hanyar nutsar da shi a cikin wani zafi mai zafi na potassium gishiri. Sun gano cewa lokacin da suka ƙara aluminum oxide zuwa abun da ke cikin gilashin kafin su nutsar da shi a cikin maganin, abin da ya haifar ya kasance mai ƙarfi da ɗorewa. Ba da daɗewa ba masanan suka fara jefa irin wannan taurin gilashin daga gininsu mai hawa tara tare da jefa bam a gilashin, wanda aka fi sani da 0317, da kajin daskararre. Gilashin na iya lankwasa da murɗawa zuwa wani mataki na ban mamaki kuma yana jure matsi na kusan 17 kg/cm. (Gilashin na yau da kullun yana iya fuskantar matsi na kusan kilogiram 850/cm.) A shekara ta 1, Corning ya fara ba da kayan da ke ƙarƙashin sunan Chemcor, yana mai imani zai sami aikace-aikace a cikin kayayyaki kamar rumfunan tarho, tagogin kurkuku, ko gilashin ido.

Kodayake akwai sha'awa mai yawa a cikin kayan a farkon, tallace-tallace ya ragu. Kamfanoni da yawa sun ba da umarni don gilashin tsaro. Duk da haka, ba da daɗewa ba an janye waɗannan saboda damuwa game da hanyar fashewar da gilashin zai iya rushewa. Chemcor da alama zai iya zama kayan aiki mai kyau don gilashin mota; ko da yake ya bayyana a cikin 'yan AMC Javelins, yawancin masana'antun ba su da tabbas game da cancantar sa. Ba su yi imani cewa Chemcor ya cancanci ƙarin farashi ba, musamman tun lokacin da suka sami nasarar yin amfani da gilashin lanƙwasa tun shekarun 30.

Corning ya ƙirƙira wani sabon abu mai tsada wanda babu wanda ya damu da shi. Babu shakka ba a taimaka masa ba ta hanyar gwaje-gwajen hatsarin, wanda ya nuna cewa tare da gilashin iska "kan mutum yana nuna raguwar raguwa sosai" - Chemcor ya tsira ba tare da lalacewa ba, amma kwanyar mutum bai yi ba.

Bayan da kamfanin ya yi ƙoƙarin sayar da kayan ga Ford Motors da sauran masu kera motoci, Project Muscle ya ƙare a 1971 kuma kayan Chemcor ya ƙare akan kankara. Magani ce da sai an jira matsalar da ta dace.

Muna cikin jihar New York, inda ginin hedkwatar Corning yake. Daraktan kamfanin, Wendell Weeks, yana da ofishinsa a hawa na biyu. Kuma a nan ne Steve Jobs ya sanya makwanni mai shekaru hamsin da biyar aiki da ga alama ba zai yiwu ba: don samar da dubban ɗaruruwan murabba'in murabba'in gilashin matsananci-baƙi da ƙaƙƙarfan gilashin da ba su wanzu ba har yanzu. Kuma a cikin watanni shida. Labarin wannan haɗin gwiwar - ciki har da ƙoƙarin Ayyuka na koyar da Makonni ka'idodin yadda gilashin ke aiki da imaninsa cewa za a iya cimma burin - sananne ne. Yadda Corning ya gudanar a zahiri ba a san shi ba.

Makonni sun shiga kamfani a 1983; a farkon 2005, ya zama babban matsayi, yana kula da sashen talabijin da kuma sashen aikace-aikace na musamman. Tambaye shi game da gilashin kuma zai gaya muku cewa abu ne mai kyau kuma mai ban mamaki, wanda masana kimiyya suka fara ganowa a yau. Zai ba da labarin "sahihancinsa" da jin daɗin taɓawa, kawai ya ba ku labarin abubuwan da ke cikin jiki bayan ɗan lokaci.

Makonni da Ayyuka sun raba rauni don ƙira da damuwa tare da daki-daki. Dukansu sun jawo hankalin manyan kalubale da ra'ayoyi. Daga bangaren gudanarwa, duk da haka, Ayyuka sun kasance ɗan kama-karya, yayin da Makonni, a gefe guda (kamar yawancin magabatansa a Corning), yana goyan bayan tsarin mulki mai 'yanci ba tare da la'akari da ƙaddamarwa ba. "Babu rabuwa tsakanina da masu bincike guda ɗaya," in ji Weeks.

Kuma hakika, duk da kasancewarsa babban kamfani - yana da ma'aikata 29 da dala biliyan 000 a cikin kudaden shiga a bara - Corning har yanzu yana aiki kamar ƙaramin kasuwanci. Wannan yana yiwuwa ne ta hanyar nisanta daga duniyar waje, adadin mace-mace yana tafiya kusan kashi 7,9% kowace shekara, da kuma sanannen tarihin kamfanin. (Don Stookey, yanzu mai shekaru 1, da sauran tatsuniyoyi na Corning har yanzu ana iya ganin su a cikin falo da dakunan bincike na wurin bincike na Sullivan Park.) "Dukkanmu muna nan don rayuwa," in ji murmushi makonni. "Mun dade da sanin juna a nan kuma mun sami nasarori da gazawa tare."

Ɗaya daga cikin tattaunawar farko tsakanin Makonni da Ayyuka a zahiri ba shi da alaƙa da gilashi. A wani lokaci, masana kimiyya na Corning suna aiki akan fasahar microprojection - mafi daidai, hanya mafi kyau don amfani da Laser na roba. Babban ra'ayin shi ne cewa mutane ba sa son kallon ƙaramin nuni a wayar hannu duk rana lokacin da suke son kallon fina-finai ko shirye-shiryen talabijin, kuma tsinkaya ya zama kamar mafita ta halitta. Koyaya, lokacin da Makonni suka tattauna ra'ayin tare da Ayyuka, shugaban Apple ya yi watsi da shi a matsayin shirme. A lokaci guda kuma, ya ambaci cewa yana aiki akan wani abu mafi kyau - na'urar da samanta gaba ɗaya ya kasance da nuni. An kira shi iPhone.

Ko da yake Ayyuka sun la'anci koren lasers, suna wakiltar "bidi'a don ƙididdigewa" wanda ke da halayyar Corning. Kamfanin yana riƙe da irin wannan girmamawa ga gwaji wanda ya sanya hannun jari mai daraja 10% na ribar da yake samu a cikin bincike da haɓaka kowace shekara. Kuma a lokaci mai kyau da mara kyau. Lokacin da kumfa mai banƙyama ta fashe a cikin 2000 kuma darajar Corning ta faɗi daga $100 rabon zuwa $1,50, Babban Jami'in nata ya tabbatar wa masu binciken ba wai har yanzu bincike ya kasance a zuciyar kamfanin ba, amma bincike da haɓaka ne suka ci gaba da tafiya. dawo da nasara.

Rebecca Henderson, farfesa a Makarantar Kasuwancin Harvard da ta yi nazarin tarihin Corning ta ce "Yana ɗaya daga cikin ƙananan kamfanoni na fasaha waɗanda ke iya sake mayar da hankali akai-akai." "Wannan abu ne mai sauqi a ce, amma da wuya a yi." Ko da Corning ya yi nasara a waɗannan hanyoyi guda biyu, sau da yawa yana iya ɗaukar shekaru da yawa don samun dacewa - kuma mai wadataccen riba - kasuwa don samfurinsa. Kamar yadda Farfesa Henderson ya ce, ƙirƙira, a cewar Corning, sau da yawa yana nufin ɗaukar ra'ayoyin da suka gaza da kuma amfani da su don wata manufa ta daban.

Tunanin ƙurawar samfuran Chemcor ya samo asali ne a cikin 2005, kafin Apple ma ya shiga cikin wasan. A lokacin, Motorola ya saki Razr V3, wayar hannu mai ɗaukar hoto wacce ta yi amfani da gilashi maimakon babban nunin filastik. Corning ya kafa wata ‘yar karamar kungiya da aka dorawa alhakin ganin ko zai yiwu a farfado da gilashin Type 0317 don amfani da su a cikin na’urori irin su wayoyin hannu ko agogo. Tsoffin samfuran Chemcor sun kasance a kauri kusan milimita 4. Watakila ana iya rage su. Bayan binciken kasuwa da yawa, hukumomin kamfanin sun gamsu cewa kamfanin zai iya samun kuɗi kaɗan daga wannan samfurin na musamman. An sanya wa aikin suna Gorilla Glass.

A shekara ta 2007, lokacin da Ayuba ya bayyana ra'ayinsa game da sabon abu, aikin bai yi nisa sosai ba. Apple a fili yana buƙatar adadi mai yawa na bakin ciki 1,3mm, gilashin daɗaɗɗen sinadarai - wani abu da ba wanda ya ƙirƙira a da. Shin Chemcor, wanda har yanzu ba a samar da shi da yawa ba, ana iya danganta shi da tsarin masana'antu wanda zai iya biyan buƙatu mai yawa? Shin zai yiwu a yi kayan da aka yi niyya da farko don gilashin mota ultra-bakin ciki kuma a lokaci guda yana kula da ƙarfinsa? Shin tsarin tauraruwar sinadarai ma zai yi tasiri ga irin wannan gilashin? A lokacin, babu wanda ya san amsar waɗannan tambayoyin. Don haka Makonni sun yi daidai abin da duk wani Shugaba mai hana haɗari zai yi. Yace eh.

Don wani abu mai banƙyama kamar wanda ba a iya gani da gaske, gilashin masana'antu na zamani yana da rikitarwa sosai. Gilashin soda-lemun tsami na yau da kullun ya wadatar don samar da kwalabe ko kwararan fitila, amma bai dace da sauran amfani ba, saboda yana iya tarwatsewa cikin kaifi mai kaifi. Gilashin Borosilicate irin su Pyrex yana da kyau kwarai wajen tsayayya da girgizar zafi, amma narkewar sa yana buƙatar kuzari mai yawa. Bugu da ƙari, akwai hanyoyi guda biyu kawai waɗanda gilashin za a iya samar da su da yawa - fasahar zana fusion da wani tsari da aka sani da floatation, wanda ake zuba narkakken gilashin a gindin narkakkar gwangwani. Ɗaya daga cikin ƙalubalen da masana'antar gilashin ke fuskanta shine buƙatar dacewa da sabon abun da ke ciki, tare da duk abubuwan da ake bukata, zuwa tsarin samarwa. Abu daya ne ka fito da dabara. A cewarsa, abu na biyu shine yin samfurin karshe.

Ko da kuwa abun da ke ciki, babban ɓangaren gilashin shine silica (aka yashi). Tun da yake yana da wurin narkewa sosai (1 ° C), ana amfani da wasu sinadarai, irin su sodium oxide, don rage shi. Godiya ga wannan, yana yiwuwa a yi aiki tare da gilashin sauƙi kuma don samar da shi mafi arha. Yawancin waɗannan sinadarai kuma suna ba da takamaiman kaddarorin ga gilashin, kamar juriya ga haskoki X ko yanayin zafi, ikon nuna haske ko tarwatsa launuka. Duk da haka, matsaloli suna tasowa lokacin da aka canza abun da ke ciki: ƙaramin daidaitawa zai iya haifar da samfurin daban-daban. Misali, idan kun yi amfani da abu mai yawa kamar barium ko lanthanum, zaku sami raguwa a wurin narkewa, amma kuna yin haɗarin cewa kayan ƙarshe ba zai zama gama gari ba. Kuma lokacin da kuka ƙarfafa gilashin, kuna kuma ƙara haɗarin fashewar fashewar idan ya karye. A takaice dai, gilashin abu ne da aka yi hukunci ta hanyar sulhu. Wannan shi ne ainihin dalilin da ya sa abubuwan da aka tsara, musamman waɗanda aka saurara zuwa takamaiman tsari na samarwa, su ne sirrin tsaro sosai.

Ɗaya daga cikin mahimman matakai na samar da gilashi shine sanyaya. A cikin yawan samar da madaidaicin gilashi, yana da mahimmanci don kwantar da kayan a hankali da kuma iri ɗaya don rage damuwa na ciki wanda in ba haka ba zai sa gilashin ya fi sauƙi karye. Tare da gilashin gilashi, a gefe guda, makasudin shine ƙara tashin hankali tsakanin ciki da waje na kayan. Gilashin zafin jiki na iya sa gilashin ya fi ƙarfi: ana fara zafi da gilashin har sai ya yi laushi sannan kuma samansa ya yi sanyi sosai. Layer na waje yana raguwa da sauri, yayin da ciki ya rage har yanzu narkakkar. Lokacin sanyaya, Layer na ciki yana ƙoƙarin raguwa, don haka yana aiki akan Layer na waje. An ƙirƙiri damuwa a tsakiyar kayan yayin da saman yana da yawa. Gilashin zafin jiki na iya karya idan muka samu ta hanyar matsa lamba na waje zuwa yankin damuwa. Duk da haka, ko da taurin gilashin yana da iyaka. Matsakaicin yuwuwar haɓaka ƙarfin kayan ya dogara da ƙimar raguwarsa yayin sanyaya; yawancin abubuwan ƙirƙira suna raguwa kaɗan kaɗan.

Dangantakar da ke tsakanin matsawa da damuwa ta fi dacewa ta hanyar gwaji mai zuwa: ta hanyar zuba narkakken gilashin a cikin ruwan kankara, muna ƙirƙirar nau'i-nau'i masu kama da hawaye, wanda mafi girman ɓangarensa zai iya tsayayya da matsi mai yawa, ciki har da maimaita guduma. Koyaya, ɓangaren bakin ciki a ƙarshen faɗuwar ya fi rauni. Lokacin da muka karya shi, dutsen dutsen zai tashi ta cikin dukan abu a cikin gudun fiye da 3 km / h, don haka ya saki tashin hankali na ciki. Abin fashewa. A wasu lokuta, samuwar na iya fashewa da irin wannan karfi da zai fitar da walƙiyar haske.

Sinadarin zafin gilashi, hanyar da aka haɓaka a shekarun 60, ta haifar da matsi mai ƙarfi kamar zafin jiki, amma ta hanyar da ake kira musayar ion. Gilashin Aluminosilicate, irin su Gorilla Glass, ya ƙunshi silica, aluminum, magnesium, da sodium. Lokacin da aka nutsar da shi a cikin narkakken potassium gishiri, gilashin yana zafi kuma yana faɗaɗa. Sodium da potassium suna raba ginshiƙi ɗaya a cikin tebur na abubuwa na lokaci-lokaci don haka suna yin kama da juna. Babban zafin jiki daga maganin gishiri yana ƙara ƙaura na sodium ions daga gilashin, kuma ions potassium, a gefe guda, na iya ɗaukar wurinsu ba tare da damuwa ba. Tunda ions potassium sun fi ions hydrogen girma, sun fi maida hankali a wuri guda. Yayin da gilashin ya yi sanyi, yana ƙara haɓakawa, yana haifar da matsi a saman. (Corning yana tabbatar da ko da musayar ion ta hanyar sarrafa abubuwa kamar zafin jiki da lokaci.) Idan aka kwatanta da zafin gilashi, taurin sinadarai yana ba da garantin damuwa mafi girma a cikin saman Layer (don haka tabbatar da ƙarfin har sau hudu) kuma ana iya amfani dashi akan gilashin kowane. kauri da siffa.

A ƙarshen Maris, masu binciken suna da sabon tsarin kusan a shirye. Duk da haka, har yanzu dole ne su gano hanyar samarwa. Ƙirƙirar sabon tsarin samarwa ya kasance ba a cikin tambaya kamar yadda zai ɗauki shekaru. Domin cika wa'adin Apple, biyu daga cikin masanan, Adam Ellison da Matt Dejneka, an dora musu alhakin gyara da kuma gyara tsarin da kamfanin ke amfani da shi cikin nasara. Suna buƙatar wani abu wanda zai iya samar da ɗimbin sirara, gilashin haske a cikin al'amuran makonni.

Masana kimiyya a zahiri suna da zaɓi ɗaya kawai: tsarin zane na fusion. (Akwai sabbin fasahohi da yawa a cikin wannan masana'anta da ke da ƙima, waɗanda sau da yawa sunayensu ba su da kwatankwacin Czech.) A yayin wannan aikin, ana zuba gilashin narkakkar a kan wani yanki na musamman da ake kira "isopipe". Gilashin yana kwararowa a ɓangarorin biyu na mafi ƙanƙan ɓangaren ƙugiya kuma ya sake haɗuwa a gefen kunkuntar ƙasa. Sannan yana tafiya akan rollers waɗanda aka saita saurinsu daidai. Da sauri suna motsawa, ƙaramin gilashin zai kasance.

Ɗaya daga cikin masana'antun da ke amfani da wannan tsari yana a Harrodsburg, Kentucky. A farkon shekara ta 2007, wannan reshe yana aiki da cikakken iko, kuma tankunansa na mita biyar ya kawo kilogiram 450 na gilashin da aka yi niyyar amfani da bangarorin LCD don talabijin a duniya kowace sa'a. Ɗaya daga cikin waɗannan tankuna na iya isa ga buƙatun farko daga Apple. Amma da farko shi wajibi ne don sake duba da dabara na tsohon Chemcor. Ba wai kawai gilashin ya zama sirara 1,3 mm ba, kuma dole ne ya zama mafi kyawun kallo fiye da na'urar cika rumfar tarho. Elisson da tawagarsa suna da makonni shida don kammala shi. Domin a gyara gilashin a cikin tsarin "fusion draw", ya zama dole don ya kasance mai sassaucin ra'ayi ko da a ƙananan yanayin zafi. Matsalar ita ce, duk abin da kuke yi don inganta elasticity shima yana ƙara maƙarar narkewa. Ta hanyar tweaking da yawa data kasance tare da ƙara wani sirri sirri, masana kimiyya sun iya inganta danko yayin da tabbatar da wani babban tashin hankali a cikin gilashin da kuma sauri ion musayar. An kaddamar da tankin a watan Mayun 2007. A cikin watan Yuni, ya samar da isasshen gilashin Gorilla don cike filayen kwallon kafa hudu.

A cikin shekaru biyar, Gorilla Glass ya tafi daga zama kayan abu kawai zuwa ma'auni mai kyau - ƙaramin rarrabuwar da ke raba jikinmu daga rayuwar kama-da-wane da muke ɗauka a cikin aljihunmu. Muna taɓa murfin gilashin na waje kuma jikinmu yana rufe kewaye tsakanin lantarki da maƙwabcinsa, yana canza motsi zuwa bayanai. Yanzu an nuna Gorilla a cikin samfuran sama da 750 daga samfuran iri 33 a duk duniya, gami da kwamfyutoci, kwamfutar hannu, wayoyi da talabijin. Idan kuna sarrafa yatsa akai-akai akan na'ura, tabbas kun riga kun saba da Gorilla Glass.

Kudaden shiga na Corning sun yi tashin gwauron zabi a cikin shekaru, daga dala miliyan 20 a shekarar 2007 zuwa dala miliyan 700 a shekarar 2011. Kuma da alama za a yi wasu amfani da gilashin. Eckersley O'Callaghan, wanda masu zanen kaya ke da alhakin bayyanar da dama na Apple Stores, ya tabbatar da wannan a aikace. A bikin Zane na London na bana, sun gabatar da wani sassaka da aka yi da Gilashin Gorilla kawai. Wannan zai iya sake bayyana a ƙarshe akan gilashin mota. Kamfanin a halin yanzu yana tattaunawa game da amfani da shi a cikin motocin wasanni.

Menene halin da ake ciki a kusa da gilashin yau? A Harrodsburg, injuna na musamman kan loda su a cikin akwatunan katako, a yi jigilar su zuwa Louisville, sannan a tura su ta jirgin kasa zuwa gabar Yamma. Da zarar an isa wurin, ana sanya filayen gilashin a kan jiragen ruwa da kuma jigilar su zuwa masana'antu a kasar Sin, inda za a gudanar da wasu matakai na karshe. Da farko ana ba su wanka mai zafi na potassium sannan a yanka su cikin ƙananan murabba'i.

Tabbas, duk da kaddarorin sihirinsa, Gorilla Glass na iya gazawa, kuma wani lokacin har ma da “yadda ya kamata”. Tana karyewa idan muka sauke wayar, sai ta koma gizo-gizo idan ta lankwashe, takan tsage idan muka zauna a kai. Har yanzu gilas ne. Kuma wannan shine dalilin da ya sa akwai ƴan ƙaramar ƙungiyar mutane a Corning waɗanda ke shafe mafi yawan rana suna rushe shi.

"Muna kiransa guduma ta Norwegian," in ji Jaymin Amin yayin da yake ciro babban silinda na ƙarfe daga cikin akwatin. Ana amfani da wannan kayan aikin ta injiniyoyin jiragen sama don gwada ƙarfin fuselage na jirgin sama. Amin, wanda ke kula da haɓakar duk sabbin kayan, ya shimfiɗa bazara a cikin guduma kuma ya saki cikakken joules na makamashi 2 a cikin takardar gilashin-bakin ciki-milimita. Irin wannan ƙarfin zai haifar da babban ƙwanƙwasa a cikin itace mai ƙarfi, amma babu abin da zai faru da gilashin.

Nasarar Gorilla Glass yana nufin cikas da yawa ga Corning. A karon farko a cikin tarihinsa, kamfanin dole ne ya fuskanci irin wannan babban bukatu na sabbin nau'ikan samfuransa: duk lokacin da ya sake fitar da sabon gilashin, ya zama dole a saka idanu kan yadda yake nuna aminci da ƙarfi kai tsaye a cikin filin. Don haka, tawagar Amin ta tattara daruruwan fasalolin wayoyin hannu. Masanin kimiyya Kevin Reiman ya ce, "Lalacewar, babba ko babba, kusan kullum tana farawa ne a wuri guda," in ji masanin kimiyyar Kevin Reiman, yana nuni da wani fashewar da ba a iya gani kusan a kan HTC Wildfire, daya daga cikin wayoyi da dama da ke kan teburin da ke gabansa. Da zarar ka sami wannan tsaga, za ka iya auna zurfinsa don samun ra'ayi game da matsin lamba da gilashin ya yi; idan za ku iya kwaikwayi wannan tsaga, zaku iya bincika yadda ya yaɗu cikin kayan kuma kuyi ƙoƙarin hana shi nan gaba, ko dai ta hanyar gyaggyara abun da ke ciki ko ta hanyar taurin sinadarai.

Tare da wannan bayanin, sauran ƙungiyar Amin zasu iya bincika gazawar kayan aiki akai-akai. Don yin wannan, suna amfani da matsi na lever, sauke gwaje-gwaje akan granite, siminti da saman kwalta, suna sauke abubuwa daban-daban akan gilashin kuma gabaɗaya suna amfani da na'urorin azabtarwa masu kama da masana'antu tare da arsenal na lu'u-lu'u. Har ma suna da kyamarar kyamara mai sauri mai iya yin rikodin firam miliyan ɗaya a cikin daƙiƙa guda, wanda ke zuwa da amfani don nazarin lankwasa gilashi da yaɗawa.

Duk da haka, duk abin da ke sarrafa lalacewa yana biya ga kamfanin. Idan aka kwatanta da sigar farko, Gorilla Glass 2 ya fi ƙarfin kashi ashirin cikin ɗari (kuma na uku ya kamata ya zo kasuwa a farkon shekara mai zuwa). Masana kimiyya na Corning sun cimma hakan ne ta hanyar matsawa matsa lamba na waje zuwa iyaka - sun kasance masu ra'ayin mazan jiya tare da sigar farko ta Gorilla Glass - ba tare da kara haɗarin fashewar fashewar abubuwan da ke da alaƙa da wannan canjin ba. Duk da haka, gilashin abu ne mai rauni. Kuma yayin da kayan da ba su da ƙarfi ke tsayayya da matsawa da kyau, suna da rauni sosai idan aka shimfiɗa su: idan kun lanƙwasa su, za su iya karye. Makullin Gilashin Gorilla shine matsi na waje, wanda ke hana tsagewa daga yadawa cikin kayan. Idan ka jefar da wayar, nunin nata bazai karye nan da nan ba, amma faɗuwar na iya haifar da isassun lalacewa (ko da faɗuwar ƙarami ya isa) don ɓata ƙarfin kayan. Ƙananan faɗuwar gaba na iya haifar da mummunan sakamako. Wannan yana ɗaya daga cikin sakamakon da babu makawa na yin aiki tare da wani abu wanda ke game da sulhuntawa, game da ƙirƙirar ƙasa mara kyau.

Mun dawo masana'antar Harrodsburg, inda wani mutum a cikin baƙar fata Gorilla Glass T-shirt yana aiki tare da takardar gilashi mai bakin ciki kamar 100 microns (kimanin kauri na foil aluminum). Na'urar da yake aiki da ita tana tafiyar da kayan ta cikin jerin rollers, inda gilashin ke fitowa a lankwashe kamar wata katuwar takarda mai haske. Wannan abu mai ban mamaki siriri kuma mai jujjuyawa ana kiransa Willow. Ba kamar Gorilla Glass ba, wanda ke aiki kamar sulke, ana iya kwatanta Willow fiye da rigar ruwan sama. Yana da dorewa da haske kuma yana da dama mai yawa. Masu bincike a Corning sun yi imanin cewa kayan na iya samun aikace-aikace a cikin ƙirar wayoyi masu sassauƙa da nunin OLED na bakin ciki. Ɗaya daga cikin kamfanonin makamashi kuma zai so ya ga ana amfani da Willow a cikin hasken rana. A Corning, har ma sun hango littattafan e-littattafai masu shafukan gilashi.

Wata rana, Willow zai ba da gilashin mita 150 akan manyan reels. Wato, idan wani ya yi oda da gaske. A halin yanzu, coils suna zaune a banza a masana'antar Harrodsburgh, suna jiran matsalar da ta dace ta taso.

nice labarin, na gode!

Labari mai ban sha'awa :) amma ina so in san yadda gilashin Gorilla ya juya a Steve :) yaya zanga-zangar aikin :)... a gaskiya, a ganina zai kasance gaba daya a 1 :)

Labari mai ban sha'awa :) amma ina so in san yadda gilashin Gorilla ya juya a Steve :) yaya zanga-zangar aikin :)... a gaskiya, a ganina zai kasance gaba daya a 1 :)

yana cikin littafin Steve Jobs ;)

na gode :)

Kyakkyawan! :-)

Kyakkyawan! :-)

Na ji daɗin karantawa kuma na koyi abubuwa da yawa. Godiya da yawa.

Labari mai daɗi sosai, na gode da shi. Mutumin ya koyi wani abu mai ban sha'awa. Marubuta daga zive.cz da spol zasu iya koyan wani abu.

Wannan shine yadda nake tunanin uwar garken game da apple! Jablickar ya jagoranci :) na gode

Ya zuwa yanzu mafi kyawun labarin akan Jablickari wannan shekara. Kuma a cikin CV na SJ babu ko kaɗan na bayanan da aka bayar anan. Godiya!

Jira, don haka iPhone na farko ya riga ya yi amfani da Gorilla, ko menene? In ba haka ba, babban labarin. :)

Haka yake. Ainihin sun canza daga filastik zuwa gilashin Gorilla a minti na ƙarshe.

Babban labari :D…. Ko akwai wanda yasan yana da iphone 5 gorilla glass 2???

Lallai babban labari! Godiya!

Abin da nake jira ke nan da kuma dalilin da ya sa na zo nan. Kawai sau da yawa, don Allah!

Babban labari! Ƙarin waɗannan kuma zan buga a gaban edita da mai fassara!

Ina sha'awar cewa a lokacin da duk wani "m" gidan yanar gizo na labarai da farko yana neman hotunan Kate da ba a buga ba (har ma sabobin gida sun manta game da Iveta Bartošová na 'yan kwanaki!), Jablíčkář yana kawo labarai masu mahimmanci. Godiya! :-)

Frodo

Na gode da babban labarin, ci gaba da shi.

Labari mai ban mamaki! Na karanta shi a cikin zama ɗaya :-), kamar babban labarin bincike (ko almarar kimiyya, hehe)

Godiya!

Na gode da babban labarin, Ina tsammanin yana da daraja saka hannun jari lokacin barci akan wani abu mai mahimmanci.

babban labarin! Godiya!

Oh, yanzu na yi mamaki sosai!

Wani ya taɓa ce mini: "Koyaushe wayar banza ce kawai!".

Ko ta yaya, a cikin wannan in ba haka ba sosai da kyau rubuta labarin, Ina rasa fa Corning rabon da makamai kayayyakin ga USAF. Tun daga shekarun 60, sun ba da gilashin zafinsu zuwa wani yanki na gaba na kokfit na jiragen yaki don kara kariya ga ma'aikatan jirgin, misali a yayin karo da tsuntsaye, amma kuma a kan makamai masu linzami. kuma idan ban yi kuskure ba, sun tattara bayanai da yawa da gogewa a nan game da haɓakawa da samar da waɗannan kayan. Kuma kamar yadda ya faru, an ɗauki fiye da shekaru 50 kafin waɗannan fasahohin su kai ga farar hula.

Babban labari, ci gaba :-)

To, irin wannan kyakkyawan rubutun da aka mayar da hankali kan fasaha, ... huluna, godiya.

Jenda Pilsenský

Allah labarin!! BTW gilashin Willow yana da ban sha'awa ... Ina matukar sha'awar ganin yadda yake aiki lokacin ƙoƙarin murƙushewa lokacin da yake kama da foil;) da kuma yadda yake tafiya tare da juriya.